Store management System

Indian manufacturing material stores are going smart. Manufacturing, a typically labour-intensive process, adopting technology to boost productivity and save costs is a step towards automating core processes to improve quality and stay competitive.

In a Material Store fulfillment center, manages thousands of inventory units in pallets or bins, that are brought in and issued to internal or external processes. In a Material Store, products generally go through the processes of receiving, put-away, storage, replenishment, Forging and casting picking, staging and issue of products to manufacturing lines. Most companies have dedicated systems and departments in place to monitor and manage inventory throughout the supply chain.

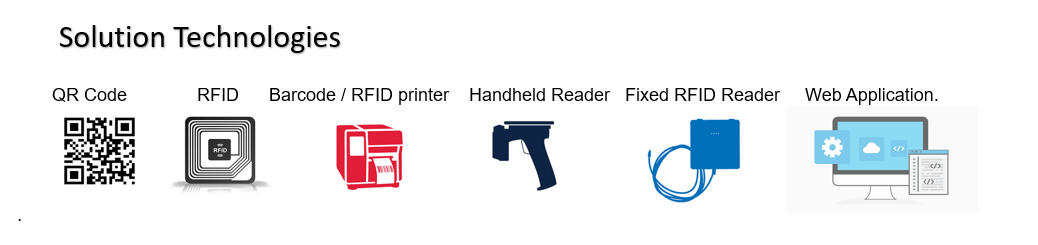

DDAPL store inventory management solution helps to manage the proper workflow to ensure the tracking of each product within the process with the help of Barcode, RFID, with customized logical workflow for put-away, replenishment and pick process ensuring optimum Space utilization, quicker put-away, location accuracy, Correct materials pick & Qty, and real time update of inventory in system on transactions.

SMS Specialties

Digital Processes

- Remove the Legacy Pen & Paper method with digital online application

- Customize the rules for storage, pick, kitting and issue of materials based on your business process.

- Update real-time each transaction in ERP or other third party applications.

- Real time accurate inventory visibility for better material planning

Increase Worker Productivity

- With Real-time updates, alerts, analytical reports and dashboard improve the Planning and Organizing Resources giving overall +20% Productivity increase.

- System Guided operations on Mobile devices provide required information on hand real time making workers execute the Order fulfilments at 1x times faster Speeds

Replenishments

- Get Alerts for the timely refill of the materials at assembly lines for smooth operations at lines.

- Set threshold Stock qty to get alerts for the materials procurement planning avoiding stock out conditions for critical materials.

- Track the Materials issue for sub contractors and out sourced processes.